Blind flanges come in different sizes and thicknesses, and they can be made from various materials, depending on the application. Stainless steel and carbon steel are often used for blind flanges, as they are durable and resistant to corrosion. Other materials like aluminum, bronze, brass or plastic may also be used in specific applications.

Blind flanges are classified by pressure ratings, such as PN6, PN10, PN16, PN25, PN40, PN63, PN100, PN160, or PN250. The PN rating indicates the maximum pressure that the flange can withstand, and it is based on the design temperature and material properties. For example, a PN6 blind flange can withstand a maximum pressure of 6 bar at room temperature.

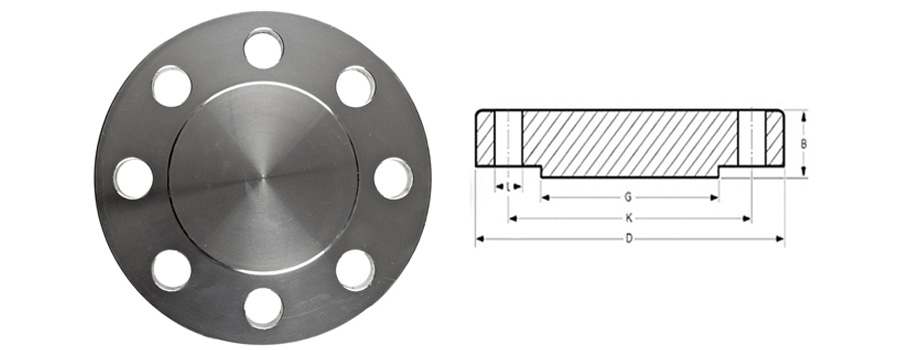

Blind flanges are available in different configurations, such as raised face, flat face, RTJ (ring type joint), tongue and groove, and others. The raised face blind flange has a raised surface around the bolt holes, which provides a sealing surface for the gasket. The flat face blind flange is flat around the bolt holes, and it requires a full-face gasket for sealing. The RTJ blind flange has a groove around the circumference, which holds a metal ring gasket for high-pressure applications. The tongue and groove blind flange has a protruding tongue on one flange and a matching groove on the opposite flange, which provides a tight seal.

Blind flanges are commonly used in applications where the process requires temporary or permanent closure of pipelines, including oil and gas, chemical, petrochemical, water treatment, and other industries. They are also used to isolate equipment for inspection, repair or maintenance. Blind flanges can be installed easily using bolts and nuts, and they can be removed easily when needed. They are also cost-effective, as they eliminate the need for costly valves or other fittings.

In conclusion, blind flanges are an essential component in piping systems, and they are available in different standards, sizes and configurations. They can be made from various materials, and they are designed to withstand different pressure ratings. Blind flanges provide a temporary or permanent seal for pipes, valves or nozzles, and they also allow for easy access for maintenance, inspection or modifications. Whether you need a blind flange for a high-pressure application or a low-pressure application, it is important to choose the right size, material and configuration to ensure optimal performance and safety.