One of the most commonly used types of flanges is the SABS flange. The South African Bureau of Standards (SABS) has set various standards and requirements for a wide range of products, including flanges. SABS flanges are widely used in several industries, including oil and gas, petrochemical, and mining.

When it comes to determining the dimensions of SABS flanges, there are specific methods that must be followed. Here are a few details on how to determine SABS flange dimensions:

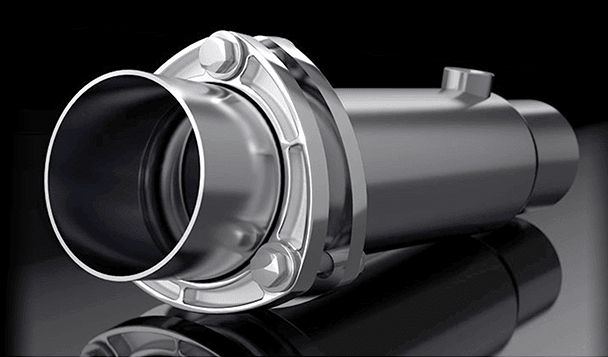

1. Determine the flange type: There are several types of flanges available, including flat welding flanges and butt welding flanges. However, it is essential to determine the exact flange type that you require before moving on to the next step.

2. Measure the flange diameter: This is the outer diameter of the flange, which must be measured in millimeters. Make sure to measure the widest point of the flange accurately, taking into account any protrusions, such as bolt holes or raised faces.

3. Determine the bolt circle and the number of bolt holes: The bolt circle is the diameter of the imaginary circle that passes through the center of each bolt hole. The number of bolt holes will depend on the flange size and type.

4. Measure the flange thickness: This is the distance between the outer edge and the inner edge of the flange. It needs to be measured in millimeters.

5. Identify the material grade: SABS flanges are available in different materials, such as carbon steel, stainless steel, and alloy steel. It is crucial to determine the material grade before proceeding with the flange installation.

By following these five steps, you can determine the correct dimensions for SABS flanges. Having accurate flange dimensions is crucial for ensuring a secure and tight seal between pipes or equipment. It also ensures that the system is functioning efficiently and safely, preventing any potential leaks or damages.

In conclusion, SABS flanges are an essential component of the piping system, ensuring safe and efficient functioning of equipment. It is necessary to follow the correct procedures and standards for determining flange dimensions, ensuring that the flanges are installed correctly and function correctly. If you are struggling with SABS flange dimensions, it is always advisable to consult with an expert engineer who can provide you with the necessary guidance and advice.