Expansion Joints: An Essential Component in Pipeline Systems

Pipeline systems have been in use for centuries, dating back to the Roman Empire. These systems have played a vital role in the transportation of oil, gas, water, and other fluids across large distances. However, as pipelines span great distances and carry fluids at high pressures, they face a variety of challenges, including vibrations, temperature changes, and ground movement. One essential component in pipeline systems designed to withstand these challenges is expansion joints.

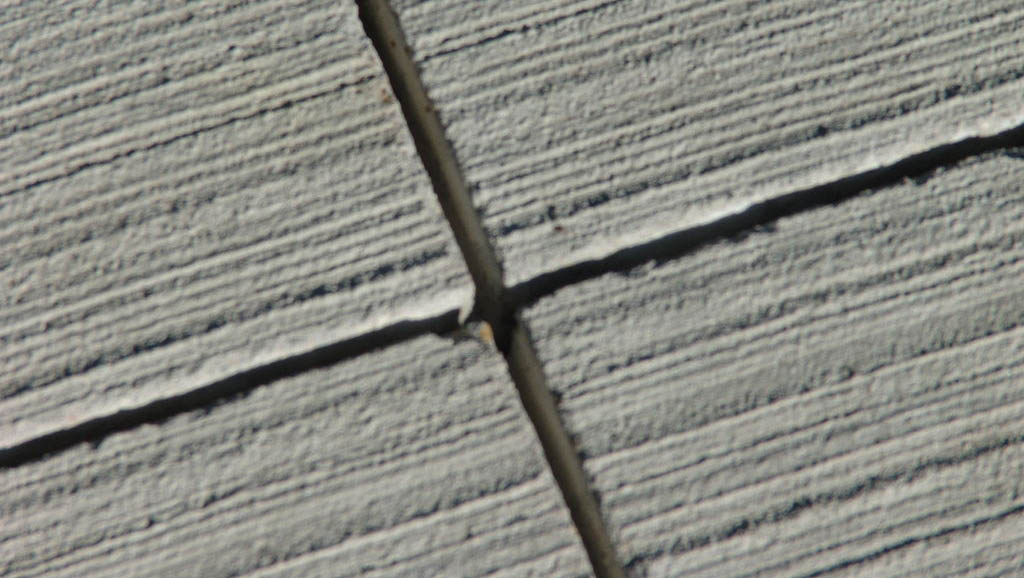

Expansion joints are devices designed to allow for the expansion and contraction of pipelines caused by temperature changes, ground movement, and other factors. These devices are typically installed at intervals along pipeline routes, allowing for lateral, angular, and axial movements in the pipeline system.

The Importance of Expansion Joints

Expansion joints are a critical component in pipeline systems, preventing damage and protecting against premature wear and tear in the pipelines. When pipelines are installed without expansion joints, the pressure from the movement can cause damage to both the pipeline and the attached fittings, leading to issues such as leaks, cracks, and even complete pipeline failure.

In addition to protecting against damage, expansion joints are also useful for improving the overall efficiency and longevity of pipeline systems. Expansion joints help to lower the amount of stress on the pipelines, reducing the risk of fatigue and improving the lifespan of the pipelines. They also help to minimize the transmission of noise and vibration throughout the pipeline system, improving the safety and comfort of those working around the pipelines.

Types of Expansion Joints

There are several different types of expansion joints on the market, each designed with specific features to meet different applications. One common type of expansion joint is the bellows expansion joint, which consists of a series of bellows linked together and fitted between pipe flanges. These joints can accommodate large amounts of movement and are ideal for pipelines that experience high levels of vibration and thermal expansion.

Another type of expansion joint is the rubber expansion joint, which is made of elastomers designed to provide flexibility and resistance to chemicals and abrasion. These joints are ideally suited for pipeline systems that handle corrosive fluids, and they can resist high temperatures and pressure.

Conclusion

In conclusion, expansion joints are a necessary component in modern pipeline systems. They help to accommodate changes in temperature, pressure, and ground movement, preventing damage, and improving the overall lifespan and efficiency of pipeline systems. With their critical role in pipeline systems, it’s essential that quality expansion joints are utilized to maintain the safety and reliability of pipelines. Hebei Xinqi Pipeline Equipment Co., Ltd. has been a leading manufacturer of high-quality pipe fittings and expansion joints for over 20 years, providing reliable solutions for pipeline systems across the world.