Product Description

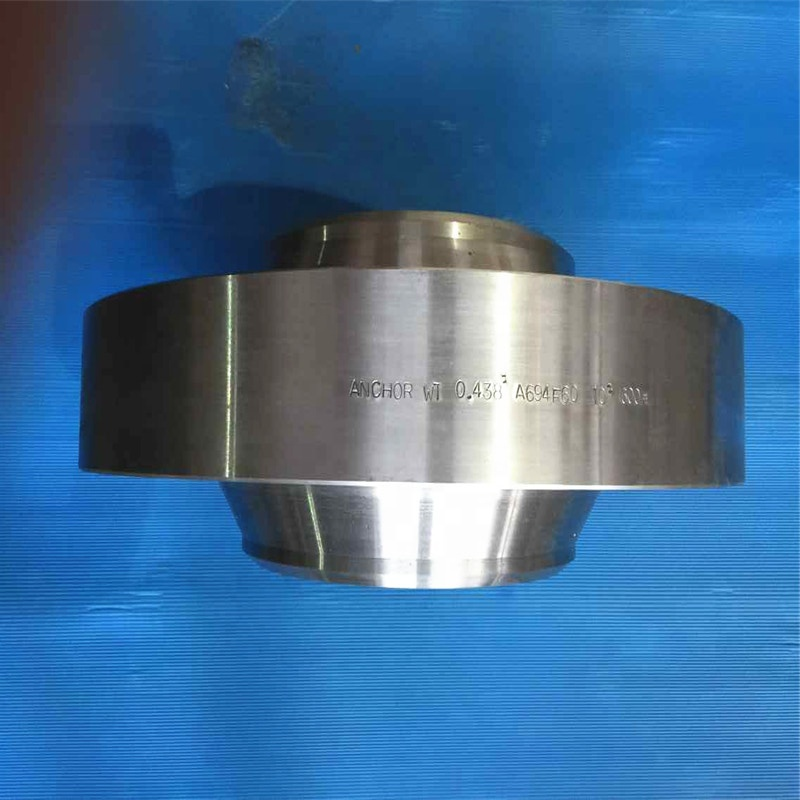

Anchoring flange is an engineering component that can be replaced by a short pipe with a thrust ring in places where the pressure is low, or is called a wall bushing, for the connection of fixed pipelines that require buried underground or lifetime maintenance, and When the pressure is required to be high, the use of conventional flanges cannot ensure the safe and reliable operation of high-pressure pipelines. The flange is an axisymmetric annular body with a flange. The two sides of the flange are symmetrical flange necks. The ports of the two flange necks are respectively welded with the ports of the pipeline and embedded in the anchoring piles. middle. Because the two flanges connected by bolts in the prior art are combined together, the gasket is eliminated, and an integral flange is made, which is connected with the pipeline by welding, and is fixed with the anchoring pile by the flange and the flange body. , which can be used to fix the connection of the pipeline. It is more suitable for the fixed connection of many process stations and line valve rooms.Product Name: Anchor Flange

| Size: | 1/2"-48" | |||||

| Pressure Rating: | Class150lb-2500lb | |||||

| Standard: | ANSI/ASME or as per customer's requets. | |||||

| Material: | Carbon Steel, Stainless Steel, Alloy Steel. | |||||

| Steel Grade: | ASTM A105, A350 LF1, A350LF2, A350LF3, ASTM A182 F304, F304L, F316, F316L, F321, A694 F42, F46, F50, F56, F60, D70 etc. | |||||

| Finish: | Rust Proof Oiled or as per customer's requirements. | |||||

The Anchor flange is a one-piece combination reducer and welding neck flange designed expressly for effecting pipe size increases at flanged connections to pumps, valves, compressors and other equipment. It provides a more compact, more efficient and frequently a more economical means than is permitted by the conventional two-piece combination of a concentric reducer and welding neck flange. Anchor flanges are used to restrain pipeline movement caused by thermal expansion changes or external forces. The most common method of securing an anchor flange is to embed it into a concrete thrust block, thereby spreading the pipeline forces throughout a large foundation. However, anchor flanges can be secured in other ways as necessary to overcome the axial force in the pipeline.

Specification of Anchor Flange

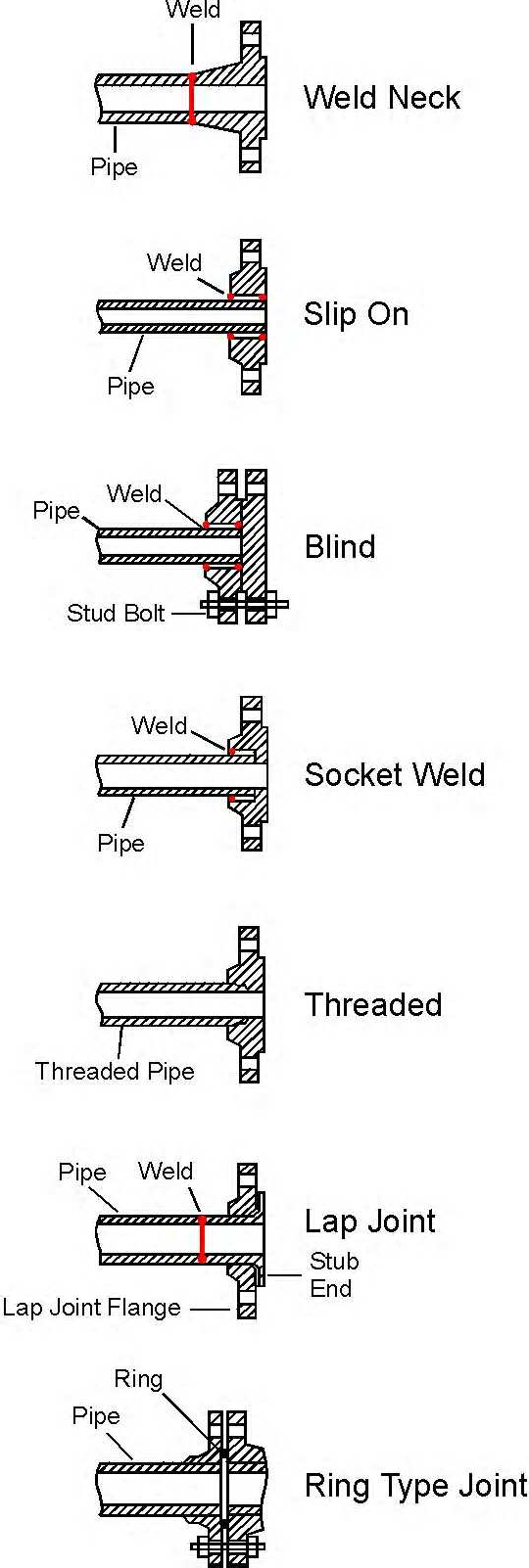

Weld Neck This flange is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications erosion inside the pipeline. The weld neck is therefore favoured in critical applications. Slip-on This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications. Blind This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange. Socket Weld This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics. Threaded This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required. Lap Joint These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel. Ring Type Joint This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.

Weld Neck This flange is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications erosion inside the pipeline. The weld neck is therefore favoured in critical applications. Slip-on This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications. Blind This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange. Socket Weld This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics. Threaded This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required. Lap Joint These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel. Ring Type Joint This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.

| Forged Anchor Flanges to ANSI, DIN ,EN1092 Standards with various sizes from 1/2"-144", with ISO9001 and TUV Certificate | |

| Material | Q235, 20#, A36, A105,A105N, SS400,ST37.2 C22.8, P250GH, S235JR, S355J2G3, 16Mn/ Q345R, SS 304,SS304L,SS316,SS316L,SS316Ti, SS321, F60,F62,F65,F70,LF2, etc. |

| Outside Coating | Rust preventing oil, spray paint (black, yellow), hot dipped galanized , cold galvanization or colored electroplate, Epoxy powder coating and so on. |

| Application area | oil, gas, chemical industry, nuclear power station, food manufacturing, construction, shipbuilding, paper making, medicine and other industries. |

| Packing | by Plywood Boxes or plywood pallets or others according to the requirements of our clients. |

•Prevents movement of the pipe due to thermal changes and external forces •Normally embedded in a concrete thrust block to spread to load over a large surface •Designed for the unique operating conditions of the pipeline

•Prevents movement of the pipe due to thermal changes and external forces •Normally embedded in a concrete thrust block to spread to load over a large surface •Designed for the unique operating conditions of the pipeline

constructions, petroleum, chemical industry, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc.

constructions, petroleum, chemical industry, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc.