| Type | Stainless steel flange,Carbon steel flange,Blind Flange |

| Standard | ASME,ANSI,DIN,JIS,BS |

| Material | Stainless steel,Carbon steel |

| Pressure | Class(150lb-2500lb) |

| Size | 1/2"-24" |

| Surface | Anti-rust Oil, Transparent/Yellow/Black Anti-rust Paint, Zinc Galvanized, Flame plating |

| Applications | Petroleum, chemical, power, gas, metallurgy, shipbuilding, construction, etc |

| Package | Standard export package,wooden case |

| Payment item | L/C, T/T, D/P, Western Union, Paypal, Money Gram |

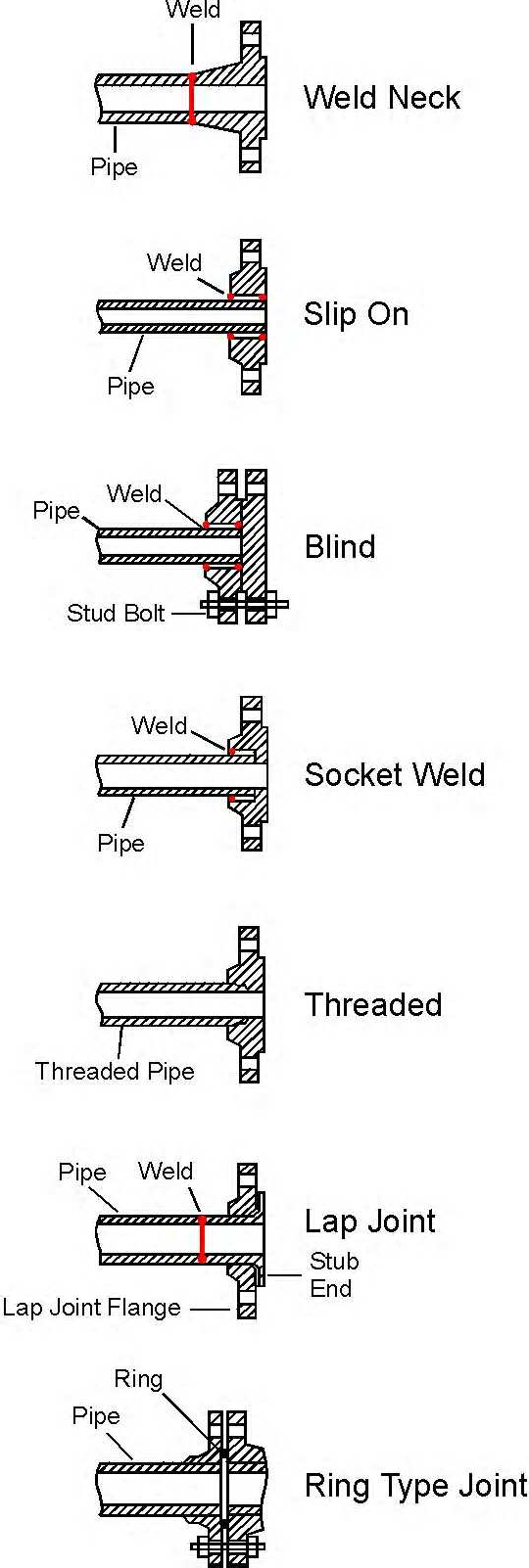

Weld Neck This flange is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications erosion inside the pipeline. The weld neck is therefore favoured in critical applications. Slip-on This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications. Blind This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange. Socket Weld This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics. Threaded This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required. Lap Joint These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel. Ring Type Joint This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.

Weld Neck This flange is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications erosion inside the pipeline. The weld neck is therefore favoured in critical applications. Slip-on This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications. Blind This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange. Socket Weld This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics. Threaded This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required. Lap Joint These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel. Ring Type Joint This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.

Product Description

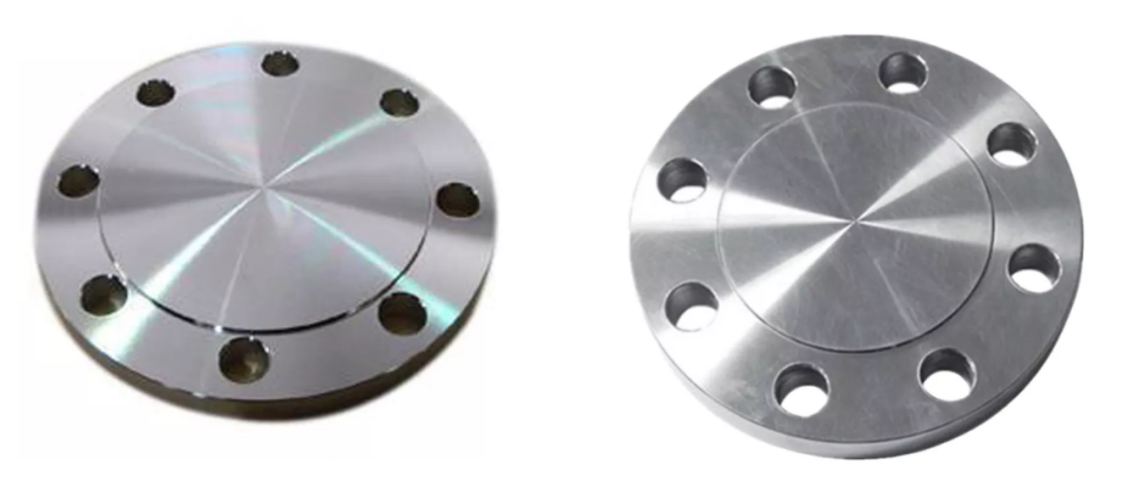

Flange blind plate, the real name is blind plate. It is a form of connection of flanges. In fact, it is a flange without a hole in the middle. One of its functions is to block the end of the pipeline, and the other is to facilitate the removal of debris in the pipeline during maintenance. As far as the blocking effect is concerned, it has the same effect as the head and the cap. However, there is no way to disassemble the head, and the flange blind plate is fixed with bolts, which is very convenient to disassemble. Flange blind plates are made of carbon steel, alloy steel, stainless steel, plastic and so on. Due to its good sealing performance, it is generally used as a reliable means of isolation for systems that require complete isolation. A blanking plate is a solid circle with a handle for systems that are normally isolated. The figure 8 blind plate is shaped like a figure 8, with a blind plate at one end and a throttling ring at the other end, but the diameter is the same as the diameter of the pipe and does not play a role in throttling. Figure 8 blind plate is easy to use. When isolation is required, the blind plate end is used. When normal operation is required, the throttle ring end is used. It can also be used to fill the installation gap of the blind plate on the pipeline. Another feature is the obvious identification, easy to identify the installation status.Specification of Blind Flange

| Size | 1/2"—72" |

| Pressure | 150# ,300#, 600#, 900#,1500#, 2500#, PN16, PN25, PN40, 5K,10K,6bar, 16bar, 25bar |

| Standard | ANSI B 16.5, ANSI B16.45, JIS B2220, DIN2633,ASME,ASTM,,JIS , DIN , EN, |

| Material | Q235, 20#, Q345A105, ST37.0,ST35.8,St37.2,St35.4/8,St42,St45,St52,St52.4 STP G38,STP G42,STPT42,STB42,STS42,STPT49,STS49 |

| Application | Low and middle pressure fluid pipeline,boiler, petroleumand natural gas industry, drilling,chemical industry,electric industry,shipbuilding, fertilizer equipment and pipeline, structure,petrochemical,pharmaceutical industry |

| Surface | Transparent anti rust oil, yellow anti rust oil, black paint,or acc. to clients request |

| Package | Plastic film, wooden cases ,wooden pallet or on customers' request |

| Certificate | ISO9001:2008, SGS,BV, etc |

| Capacity | 50000tons/year |

| Advantages | 1.Reasonable price with excellent quality2.Abundant stock and prompt delivery 3.Rich supply and export experience, sincere service 4. Reliable forwarder, 2-hour away from port. |

Products Display

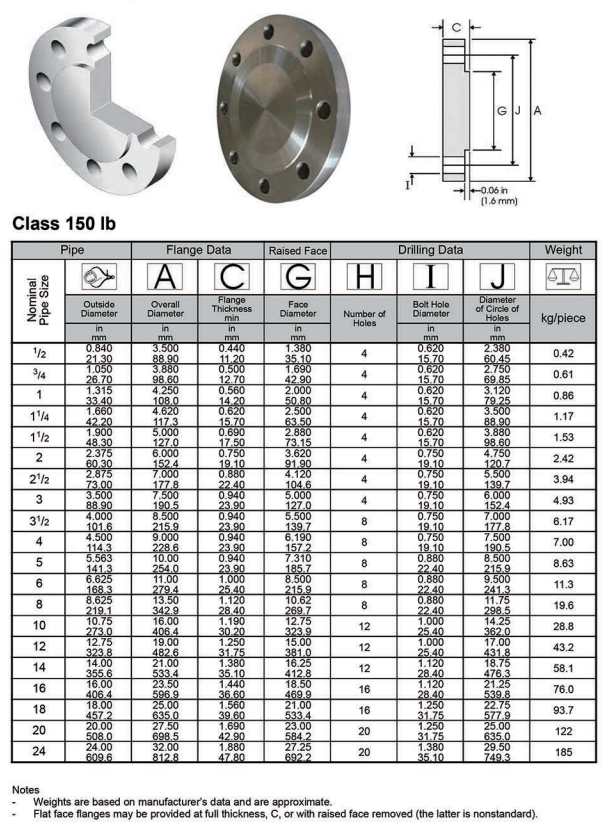

Main Connection Size of Blind Flange

constructions, petroleum, chemical industry, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc.

constructions, petroleum, chemical industry, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc.