Threaded flange refers to a kind of flange that uses threads to connect with pipes. Threaded flange is a kind of non-welding flange, which processes the inner hole of the flange into pipe threads, and is matched with the threaded pipe to realize the connection. Compared with the flat welding flange or the butt welding flange, the threaded flange has the characteristics of convenient installation and maintenance, and can be used on some pipelines where welding is not allowed. Alloy steel flanges have sufficient strength, but are not easy to weld, or the welding performance is not good, and threaded flanges can also be selected. However, when the temperature of the pipeline changes rapidly or the temperature is higher than 260°C and lower than -45°C, it is recommended not to use threaded flanges to avoid leakage.

Threaded flange refers to a kind of flange that uses threads to connect with pipes. Threaded flange is a kind of non-welding flange, which processes the inner hole of the flange into pipe threads, and is matched with the threaded pipe to realize the connection. Compared with the flat welding flange or the butt welding flange, the threaded flange has the characteristics of convenient installation and maintenance, and can be used on some pipelines where welding is not allowed. Alloy steel flanges have sufficient strength, but are not easy to weld, or the welding performance is not good, and threaded flanges can also be selected. However, when the temperature of the pipeline changes rapidly or the temperature is higher than 260°C and lower than -45°C, it is recommended not to use threaded flanges to avoid leakage.  constructions, petroleum, chemical industry, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc.

constructions, petroleum, chemical industry, ship building, paper making, metallurgy, water supply and sewage work, light and heavy industry, plumbing and electric etc.| Place of Origin: | Hebei, China | Brand Name: | Hebei Xinqi |

| Shape: | Round Plate | Standard: | ANSI/ASME B16.5,BS4504,GOST,DIN,UNI,EN1092,JIS B2220,API 6A,SABA1123,etc |

| Product name: | ASTM A105 Threaded NPT Class 150 RF Flange ANSI B16.5 | Pressure: | Class150/300/600/9001500/2500 |

| Technics: | Forged+CNC | Technology: | Casting Forging Stumping |

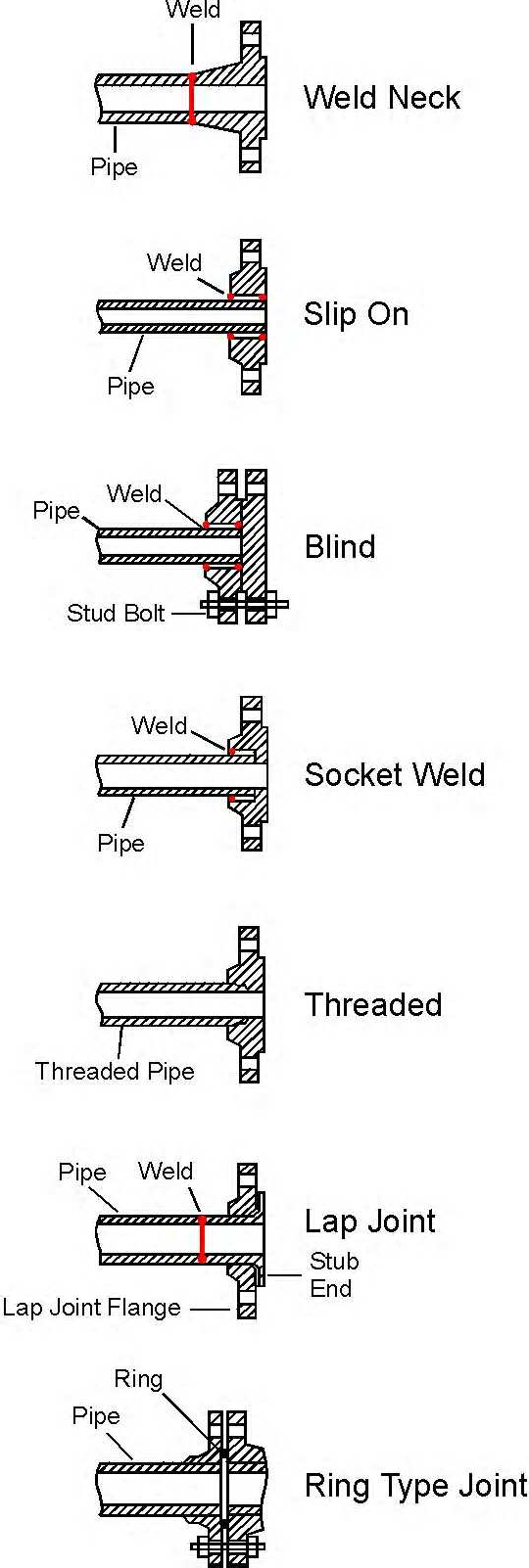

| Type: | WN THREAD BL SW LJ | Payment terms: | L/C T/T (30%DEPOSIT) |

| Surface treatment: | Galvanized |