Product Data

Product Introduction

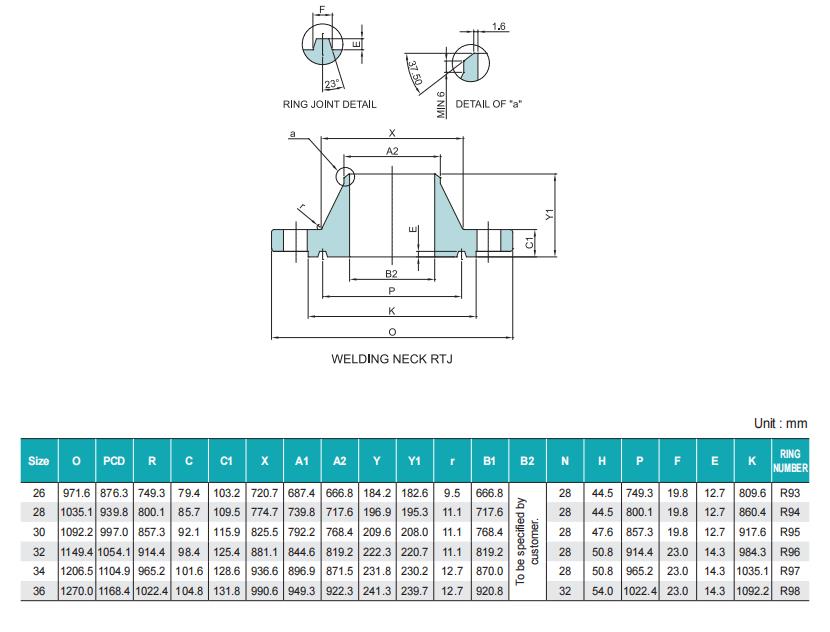

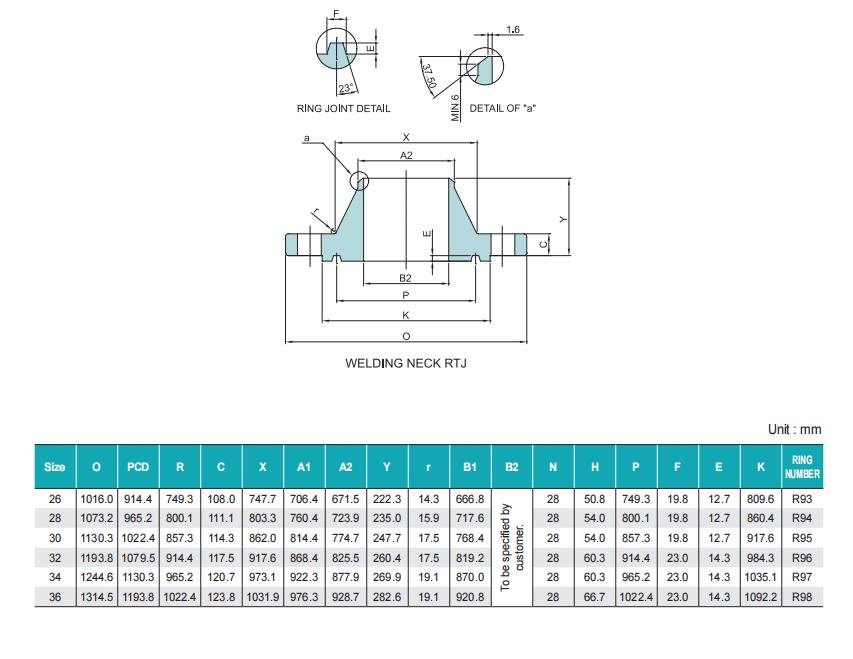

Welding Neck RTJ flange refers to a type of neck welding flange connection method with a boss and circular groove. BS3293 is a standard specification used for the design and manufacturing of steel butt welded flanges. RTJ is the abbreviation for Ring Type Joint, which means ring gasket seal.

The Welding Neck RTJ flange usually consists of three parts: the flange itself, flange washer (RTJ washer), and fasteners such as bolts and nuts. This type of flange connection method uses butt welding to connect the flange to the pipeline, and uses RTJ gaskets to form a seal between the flange and the flange, thereby preventing fluid leakage.

Size

The size of RTJ with neck welding flange is usually determined by the diameter and wall thickness of the connected pipeline or equipment. For example, in the ANSI B16.5 standard, the size range of RTJ flanges is from 1/2 inch to 36 inch, and the thickness range of connecting pipes is from SCH 10 to SCH 160.

Pressure level

The pressure rating of RTJ flanges is usually determined by their material and size. In the ANSI B16.5 standard, the pressure rating of RTJ flanges ranges from 150 pounds to 2500 pounds, and other standards also have similar pressure rating options.

Application scope

Neck welded flange RTJ is commonly used in pipeline systems under high pressure and high temperature environments, such as petrochemical, natural gas extraction, power generation, shipbuilding, and marine industries. They can connect various types of pipelines and equipment, such as valves, pumps, pressure vessels, etc., and provide reliable sealing and connection performance.

Advantage:

1. Able to withstand working requirements in high-pressure and high-temperature environments

2. High tightness and less prone to leakage

3. The annular sealing surface can be reused

Disadvantages:

1. Special metal ring gaskets are required,

2. It is necessary to strictly control factors such as pre tightening force

3. Both installation and maintenance require professional personnel to operate.

Therefore, BS3293 neck welded flange RTJ is suitable for pipeline systems that require harsh conditions such as high pressure, high temperature, strong acid and alkali, and reliable sealing measures need to be adopted to ensure operational safety and environmental protection requirements.