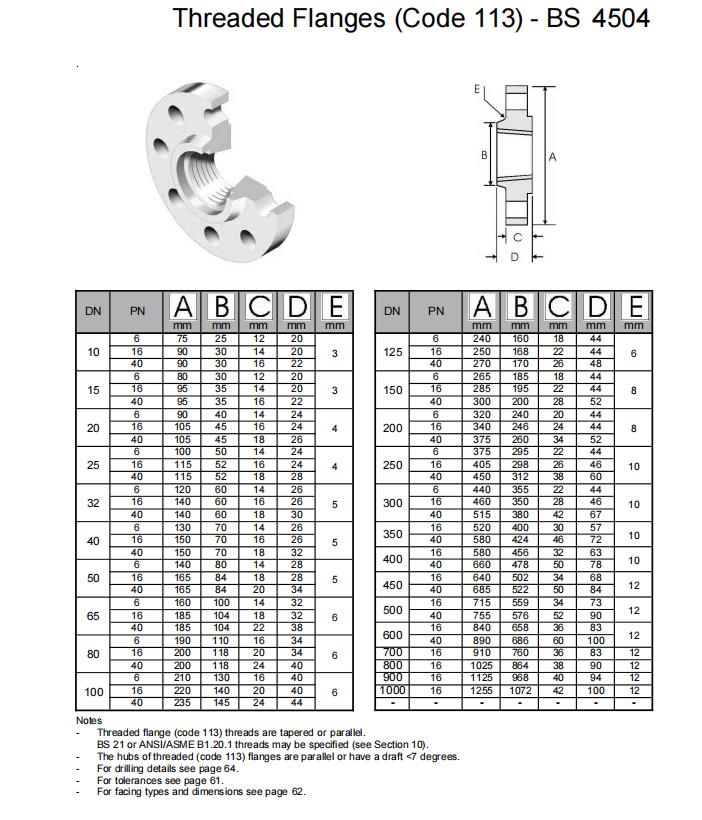

Data

Product Introduction

Threaded flange refers to a kind of flange that is connected with pipeline by thread. During design, it can be treated as loose flange. The advantage is that welding is not required, and the additional torque generated by flange deformation on the cylinder or pipe is very small. The disadvantages are large flange thickness and high cost. It is applicable to the connection of high-pressure pipes.

Implementation principle

The threaded flange is a non-welded flange, which processes the inner hole of the flange into pipe thread and connects with the threaded pipe. Compared with flat welding flange or butt welding flange, threaded flange has the characteristics of convenient installation and maintenance, and can be used on some pipelines that are not allowed to be welded on site. Alloy steel flange has sufficient strength, but it is not easy to weld, or the welding performance is not good, threaded flange can also be selected. However, when the pipeline temperature changes sharply or the temperature is higher than 260 ℃ and lower than - 45 ℃, it is recommended not to use threaded flange to avoid leakage.