ASME B16.48 spectacle blind Flange,Figure 8 Flanges,A182 F316L spectacle blind Flange

The 8-shaped blind plate is a kind of pipe parts, mainly for the convenience of inspection and repair. You can know the specific shape by painting the upper part of the "8" black. It is half a blind plate and half an iron ring. It is commonly used for pipeline flanges that need to change the process. The materials are mainly carbon steel, stainless steel, alloy, and can be selected according to the pipeline pressure level and the pipeline medium. We can manufacture Spectacle Blind Flange with different type of joint face (RF, FF, RTJ) in series 150/300/600/900/1500/2500 in according to major dimensional standards ASME B16.48. Spectacle blind Flange ,also known as figure 8 Flange which is combination of the two that can be rotated to function as Single Bind or a Ring Spacer. This kind of flange is generally a piece of metal than is cut to fit between two pipe flanges and usually sandwiched between two gaskets a spectacle blind is often made from two metal discs that are attached to each other by a small section of steel. The Sharp is similar to a pair of glasses or spectacles - hence the name spectacle blind flange. One end of the blind will have an opening to allow flow through the pipe during operation and the other end is solid to block flow during maintenance. They are generally installed as a permanent device to separate process piping system. The whole idea of a spectacle blind Flange is so that one can be absolutely sure that an item of equipment is properly and securely blanked off with no possibility of any flow or leakage through a valve during maintenance. The flow can be diverted to other items of equipment but not just by passed around the blank as this would compromise the safety function of the spectacle blind. The flow has to valve off and pressure relieved prior to loosening flange bolts and swinging the blind. Weld Neck This flange is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications erosion inside the pipeline. The weld neck is therefore favoured in critical applications. Slip-on This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications. Blind This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange. Socket Weld This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics. Threaded This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required. Lap Joint These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel. Ring Type Joint This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.

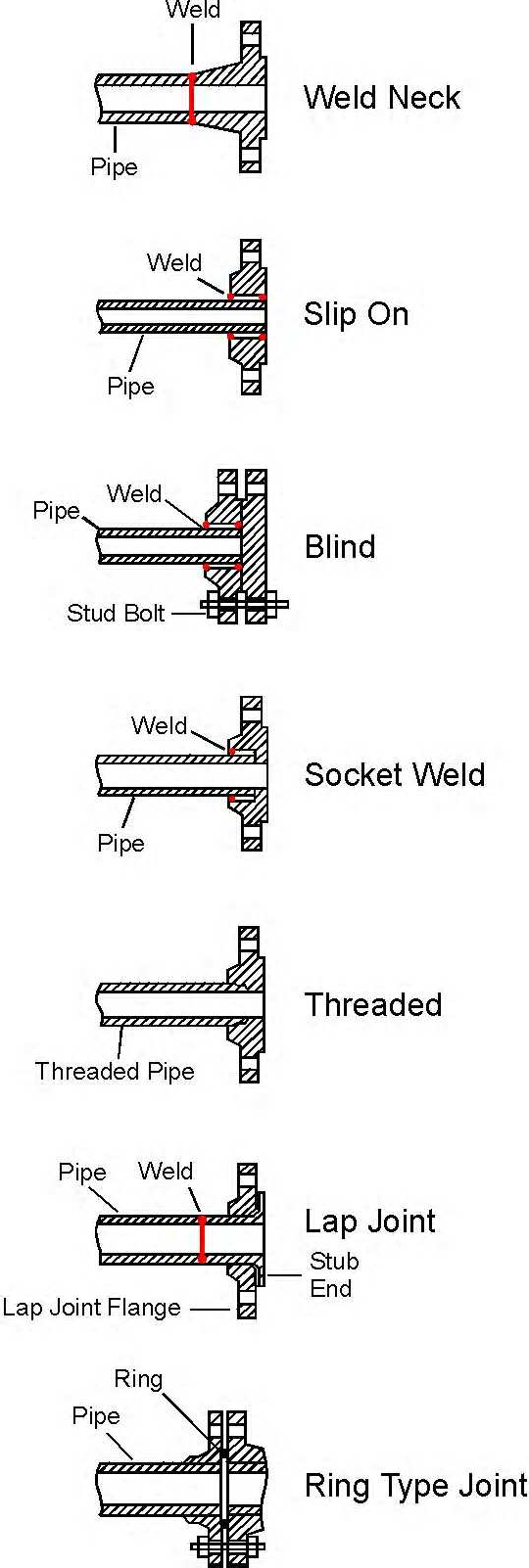

Weld Neck This flange is circumferentially welded into the system at its neck which means that the integrity of the butt welded area can be easily examined by radiography. The bores of both pipe and flange match, which reduces turbulence and erosion inside the pipeline. The weld neck is therefore favoured in critical applications erosion inside the pipeline. The weld neck is therefore favoured in critical applications. Slip-on This flange is slipped over the pipe and then fillet welded. Slip-on flanges are easy to use in fabricated applications. Blind This flange is used to blank off pipelines, valves and pumps, it can also be used as an inspection cover. It is sometimes referred to as a blanking flange. Socket Weld This flange is counter bored to accept the pipe before being fillet welded. The bore of the pipe and flange are both the same therefore giving good flow characteristics. Threaded This flange is referred to as either threaded or screwed. It is used to connect other threaded components in low pressure, non-critical applications. No welding is required. Lap Joint These flanges are always used with either a stub end or taft which is butt welded to the pipe with the flange loose behind it. This means the stub end or taft always makes the face. The lap joint is favoured in low pressure applications because it is easily assembled and aligned. To reduce cost these flanges can be supplied without a hub and/or in treated, coated carbon steel. Ring Type Joint This is a method of ensuring leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flanges.