Product Description

The reducer whose center is in a straight line is called concentric reducer. The commonly used forming process is reducing, expanding or reducing plus expanding, and stamping can also be used for reducing pipes of certain specifications.

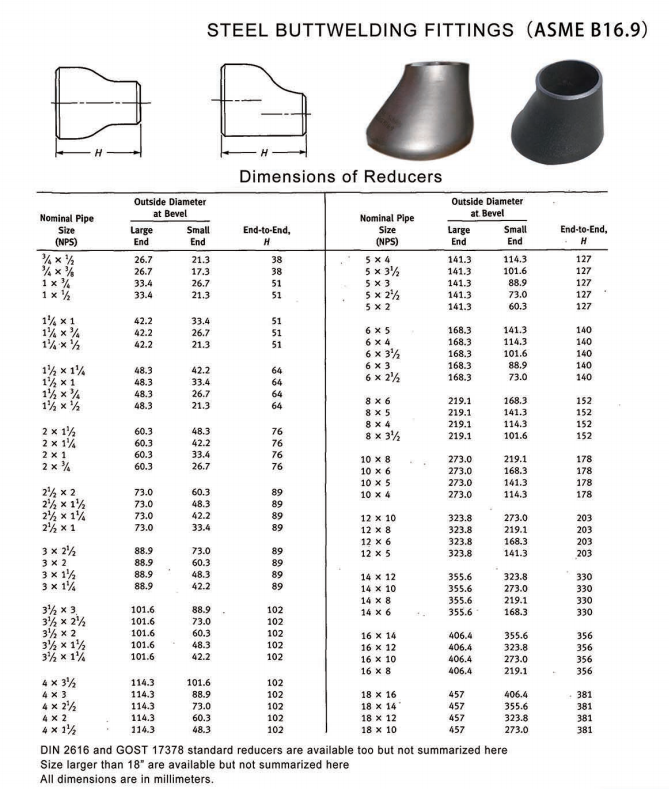

Product specification:3/4 "X1/2" --- 48 "X 40" [DN 20 X 15 --- 1200 X 1000]

Wall thickness dimension: Sch 5s --160

Executive standards: GB/T12459-2005, ANSI, JIS, BS, DIN, UNI, etc

Product material: carbon steel, stainless steel

Packaging method: fumigation free wooden cases and pallets can be specially packaged according to customer requirements.

Product use

Oil and gas pipeline project, natural gas pipeline project, chemical plant, power plant, shipyard, pharmacy, dairy, beer, beverage, water conservancy, etc

Note: carbon steel: 10 #, 20 #, A3, Q235A, 20G, 16Mn, ASTM A234, ASTM A105

Distribution characteristics

(1) The bending moment caused by the area pressure difference between the big and small ends of the concentric reducer under the action of internal pressure causes the phenomenon that the big end opens relatively and the small end shrinks relatively;

(2) Under the action of internal pressure, the circumferential stress on the inner surface of the large end of the eccentric side and the outer surface of the middle of the eccentric side of the eccentric reducer is the largest.

Advantages of carbon steel

1. Carbon steel can obtain higher hardness and better wear resistance after heat treatment.

2. The hardness of carbon steel in the annealed state is very moderate, and it also has good machinability.

3. The raw materials of carbon steel are very common, easy to get, and the production cost is relatively low.