Product Description

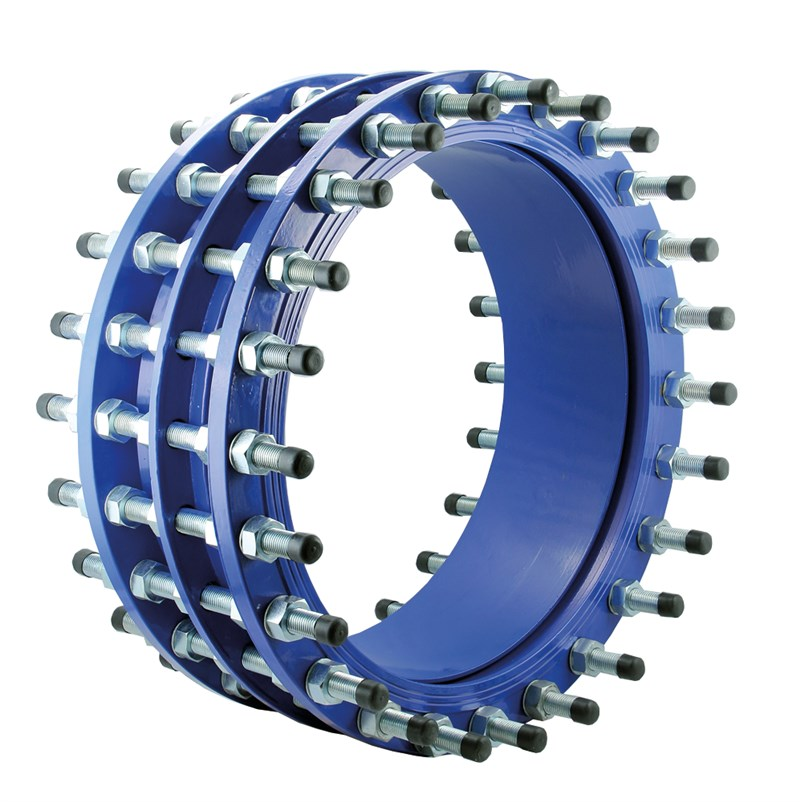

The dismanting joint consists of the main body, the sealing ring, the gland, the telescopic short pipe and other main parts. It is a new product that connects pumps, valves and other equipment with pipelines. It connects them into a whole through full bolts, and has a certain displacement. In this way, it can be adjusted according to the installation size on site during installation and maintenance, and the axial thrust can be transferred back to the whole pipeline during work. This not only improves work efficiency, but also plays a certain protective role for pumps, valves and other equipment.Advantage

Double flange power transmission joint is composed of flange loose sleeve expansion joint, short pipe flange, power transmission screw and other components, which can reduce the pressure thrust (blind plate force) of connected parts and compensate the installation error of pipeline. Double flange power transmission connection is mainly used for loose sleeve connection of pump, valve and other accessories. 1. Both ends are connected by flange, which is convenient and fast for installation. 2. It can transmit the axial thrust to the whole pipeline and spread the pressure. 3 convenient for disassembly and maintenance of pump valve.Material of Dismantling Flexible Joint

| DN/NPS | DN 50 – 2800 |

| Flange connection | PN 10, PN 16, PN 25, PN 40 |

| Operating pressure | PN 10, PN 16, PN 25, PN 40 |

| Body | AISI 304, GGG 40/50, blue epoxy coated |

| Tie bar | AISI 304, electrostatic galvanized, hot dipped galvanized, others on request |

| Nuts | AISI 304, AISI 316, AISI 316 with delta seal and messing, electrostatic galvanized, hot dipped galvanized |

| Washers | AISI 304, AISI 316, electrostatic galvanized, hot dipped galvanized, POM/Nylon |