Brief Introduction

The full name of slip-on welding flange is slip-on welding steel pipe flange. It is a flange that extends steel pipes, pipe fittings, etc. into the flange and connects with equipment or pipes through fillet welds.

Because of the diversity of the sealing surface and the advantages of its design shape, the slip-on welding flange with neck is not easy to be deformed and has good sealing performance, and is widely used;

Full English name of slip-on steel pipe flange with neck: Slip-on; Abbreviated as SO

Function

The neck flat welding flange is the same as the plate flat welding flange, which extends the steel pipe and pipe fittings into the flange and connects with the equipment or pipeline through fillet weld.

Sealing form RF, FM, M, T, G, FF.

The diameter range of neck slip-on welding flange: DN10~DN600.

Scope of application

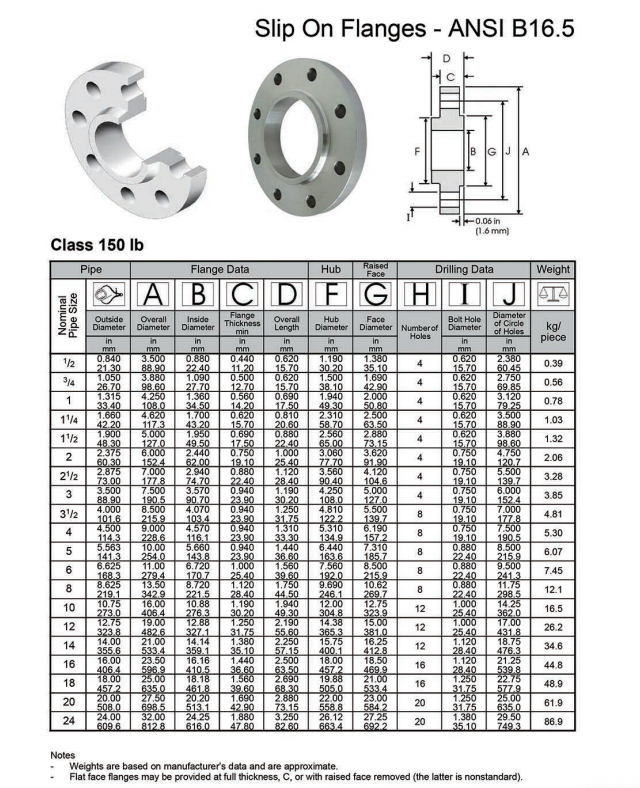

PN series PN2.5~PN40; Class series Class150~Class1500

Flange material: carbon steel, Luomo steel, 304, 316, 304L, 316L, 321, 347, CF8C.

Advantages and Disadvantages

Advantages:

The neck flat welding flange is also a flat welding flange, because it has a short neck, which improves the strength of the flange and the bearing strength of the flange. So it can be used on pipes with higher pressure. It not only saves space and reduces weight, but also ensures that the joint will not leak and has good sealing performance;

Disadvantages:

Compared with plate-type flat welding flange, the cost is higher. Because of its shape characteristics, it is easier to bump during transportation.

Material of carbon steel slip on flange

Carbon steel flange: ASTM A105,20 #, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

The commonly used materials are 20 #, Q235 and 16Mn.

Production process of Slip on flange

1: Pure material forging, highly precise lathe processing.

2: The whole forging process of round steel;

3: sawing, heat treatment, die forging and machining;