Brief Introduction

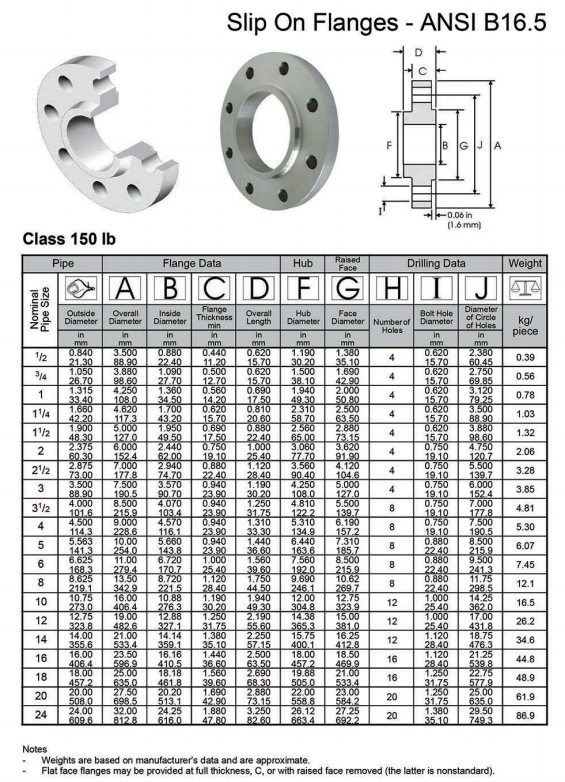

Plate type flat welding flange is the most common flange, and the common pressure is PN2.5, PN6, PN10, PN16, PN25.

Welding method: first insert the steel pipe into the inner diameter of the flange for one-sided welding, and then fasten it with bolts on both sides;

Plate type flat welding flange material: 304,316,316L, carbon steel, alloy steel, etc.

Sealing surface form: full plane (FF), raised face (RF)

Scope of application

Plate type flat welding flange has the advantages of convenient material, simple manufacture, low cost and wide use; However, due to its poor rigidity, it should not be used in chemical process piping systems with requirements of supply and demand, flammability, explosiveness and high vacuum, and in highly and extremely hazardous situations.

In addition, due to its good comprehensive performance, the flat welding flange is widely used in chemical engineering, construction, water supply, drainage, oil, light and heavy industry, refrigeration, sanitation, water heating, fire protection, electric power, aerospace, shipbuilding and other basic projects.

Characteristic

Beautiful appearance, smooth surface, acid and alkali resistance, corrosion resistance, strong texture performance;

Common materials of carbon steel: ASTM A105,20#、Q235、16Mn、ASTM A350 LF1,LF2 CL1/CL2,LF3 CL1/CL2、ASTM A694 F42,F46,F48,F50,F52,F56,F60,F65,F70;

Advantages and Disadvantages of Carbon Steel Plate Flat Welding Flange

Advantage:

1. The flat welding flange not only saves space and reduces weight, but also ensures that the joint will not leak and has good sealing performance;

2. The compact flange size is due to reducing the diameter of the seal, which will reduce the section of the sealing surface;

3. The flange gasket has been replaced by the sealing ring to ensure that the sealing face matches the sealing face;

4. It reduces the mass and space and plays an important role in industrial use;

Disadvantages:

The main design disadvantage of flat welding flange is that it cannot guarantee no leakage;

Shortcomings in its design: the connection is dynamic, and such as thermal expansion and fluctuating periodic load will cause the movement between flange faces, affect the function of the flange, thus damaging the integrity of the flange, and ultimately leading to leakage;

It is impossible for any product to be free of defects, but try to control the defects of the product to a lesser extent, so try to improve the performance of the product when producing the flat welding flange to make it play a greater role;