Product Data

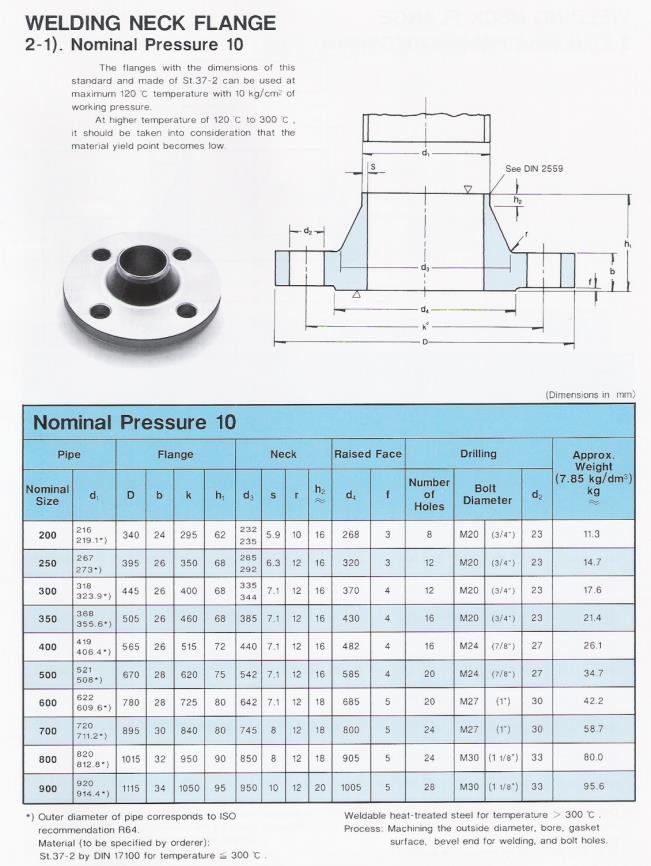

| Welding Neck Flange | |||||||||

| Standard | ANSI | ANSI B16.5, ASME B16.47 series A/B | |||||||

| DIN | Germany 6bar, 10bar, 16bar, 25bar, 40bar | ||||||||

| GOST | GOST 12820/12821/12836 | ||||||||

| EN1092-1 | EN1092-01/05/11/12/13 | ||||||||

| JIS | JIS B 2220-1984, KS B1503, JIS B 2216 | ||||||||

| BS4504 | BS4504 BS10 Table D/E | ||||||||

| Sealing Surface Form | FF、RF、M、FM、T、G、RJ | ||||||||

| Material | ASTM A105 ST37.0 A350 LF2 A694 F60 A694 F70 SS304 SS321 SS316 | ||||||||

| Nominal Pressure | DN15-DN2000 | ||||||||

| Applicable Medium | oil,gas,water or other medium; | ||||||||

| Technology | Forge&CNC machining | ||||||||

| Delivery Time | 15-60 days | ||||||||

| Payment Term | FOB,CIF | ||||||||

| Packaging | Plywood cases | ||||||||