Product Description

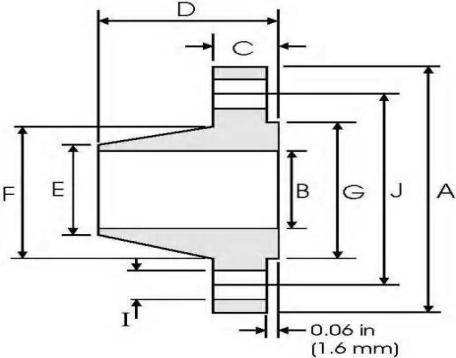

Neck butt welding flange refers to a flange with a tapered neck and butt welding with the cylinder or pipe. It is an integral flange. Due to the transition structure of the tapered neck and the butt welding connection, the strength and rigidity of the flange are strengthened,and the sealing performance is better than that of the flat welding flange. The disadvantage is that it needs to be made of forgings, which consumes a lot of materials and costs a lot. It is suitable for occasions with high pressure, high temperature or high sealing requirements. Sealing surface forms are divided into: convex surface (RF), concave surface (FM), convex surface (M), tenon surface (T), groove surface (G), full plane (FF).Features

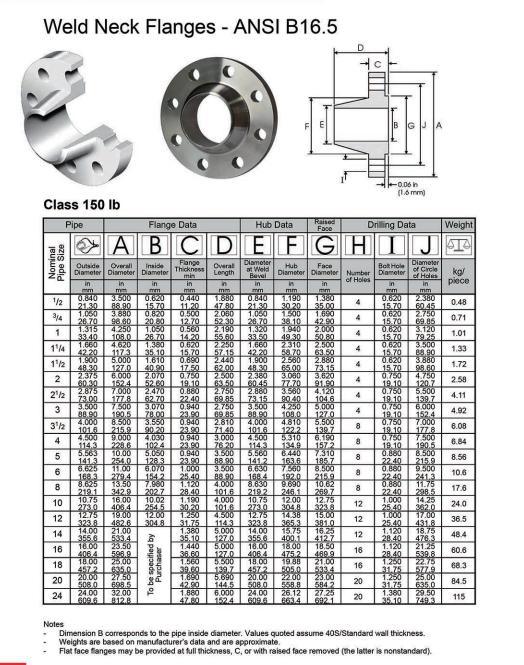

| Product name | Flange(304/F304 WN/FFRF/RTF ASME/ANSI B16.5 class150lb-2500lb Forged Stainless Steel Weld Neck Flange) |

| Size | 1/2’’~24’’ |

| Pressure | Class(150lb-2500lb) Pn(2.5-40) |

| Standard | ASME/ANSI B16.5,DIN,GOST-12821,GOST-33259JIS B2220,BS 4504 and etc. |

| Material | Stainless Steel |

| Carbon Steel | |

| Duplex stainless steel | |

| Pipeline steel | |

| Nickel alloy | |

| Application | Petrochemical industry;Aviation and aerospace industry;Pharmaceutical industry;Gas exhaust;Power plant;Ship building;Water treatment,etc. |

| Advantages | Ready stock;Faster delivery time;Available in all sizes;Customized;High quality |

The Difference Between SO And WN

1. Different weld types

Slip On Flanges: fillet weld is used for welding between flange pipe and flange. Weld Neck Flanges: the welding seam between flange and pipe is circumferential weld.2. Different materials

Slip On Flanges is machined from ordinary steel plate with thickness meeting the requirements. Weld Neck Flanges is mostly machined from forged steel.3. Different nominal pressures

Nominal pressure of Slip On Flanges: 0.6 -- 4.0MPa, Nominal pressure of Weld Neck Flanges : 1-25MPa,4.Different structures

Slip On Flanges: Refers to the flange that extends steel pipes, pipe fittings, etc. into the flange and connects with equipment or pipes through fillet welds. Weld Neck Flanges: A flange with neck and a pipe transition, which is connected with the pipe by butt welding.5. Scope of application

Slip On Flanges : There is a short neck, which increases the strength of the flange and improves the bearing capacity of the flange. So it can be used on higher pressure pipelines. Weld Neck Flanges: Suitable for pipelines with large fluctuations in pressure or temperature or pipelines with high temperature, high pressure and low temperature, for the connection of pipelines and valves with PN greater than 2.5MPa; also used for transportation of expensive and flammable , on the pipeline of explosive medium.Data Parameter