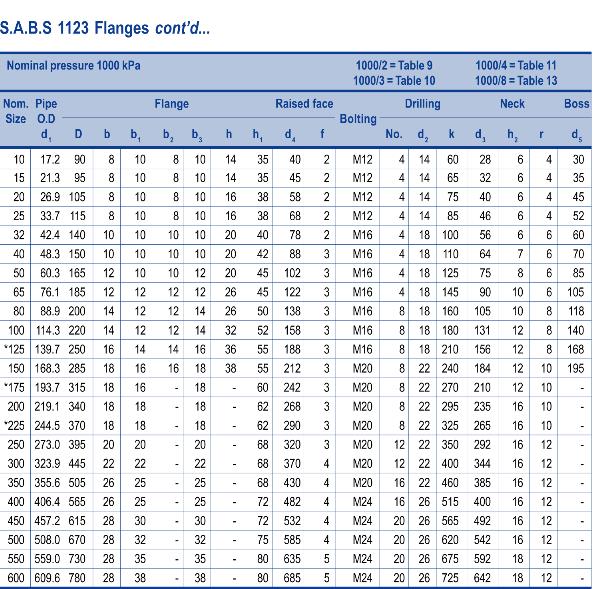

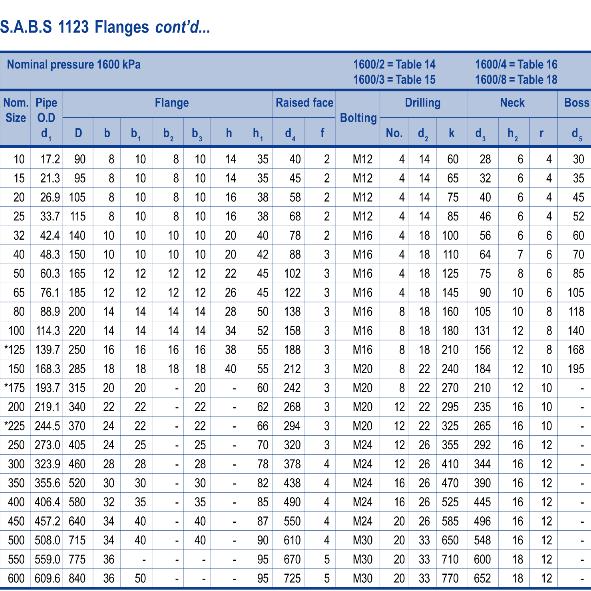

Product Data

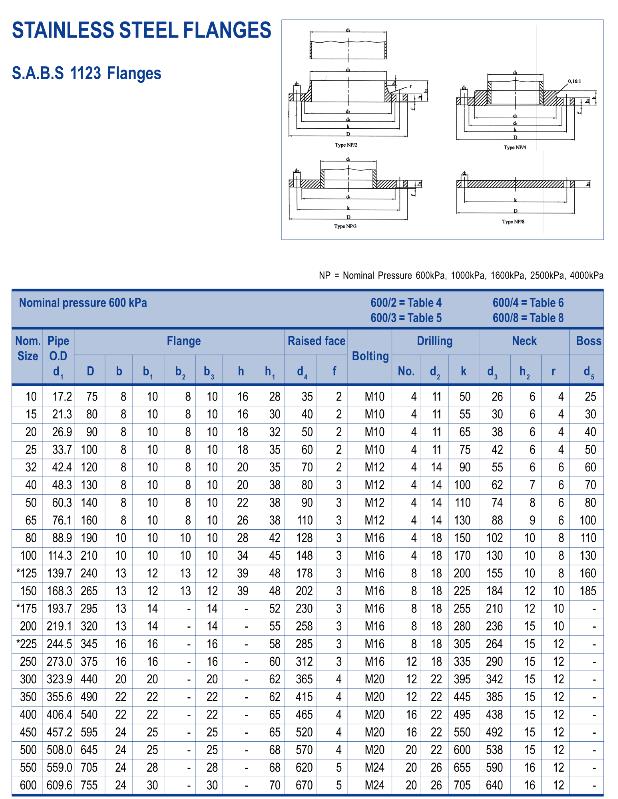

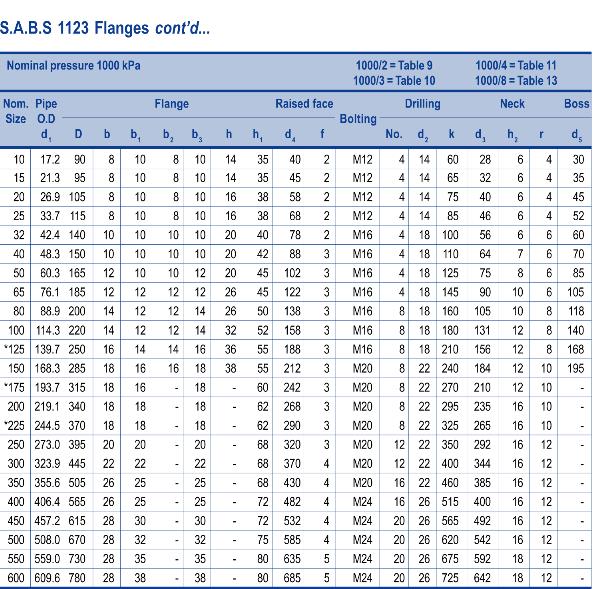

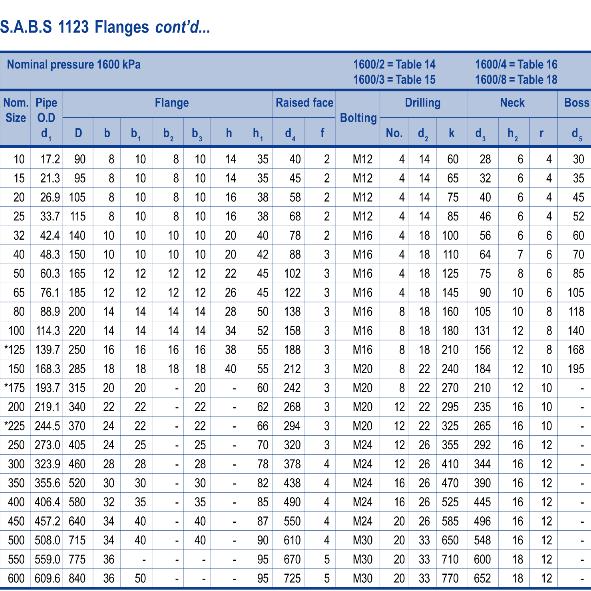

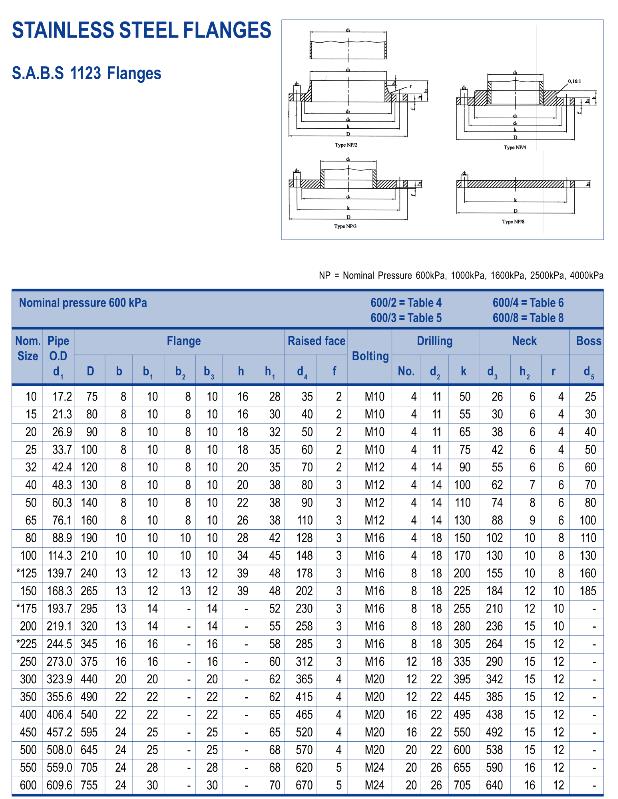

| Standard | Type | Standard | Facing | Size | Rating |

| SANS1123 | THREADED | SANS1123 600/4, SANS1123 1000/4 SANS1123 1600/4, SANS1123 2500/4 SANS1123 4000/4 | FF,RF | NB10-NB150 | 600Kpa-4000Kpa |

| Standard | Type | Standard | Facing | Size | Rating |

| SANS1123 | THREADED | SANS1123 600/4, SANS1123 1000/4 SANS1123 1600/4, SANS1123 2500/4 SANS1123 4000/4 | FF,RF | NB10-NB150 | 600Kpa-4000Kpa |