Data

Product Introduction

Socket welding flange is a flange welded with steel pipe at one end and bolted at the other end.

1. Sealing surface form: raised face (RF), concave and convex face (MFM), tenon and groove face (TG), ring joint face (RJ)

2. Material: carbon steel: ASTM A105, 20 #, Q235, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel: ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

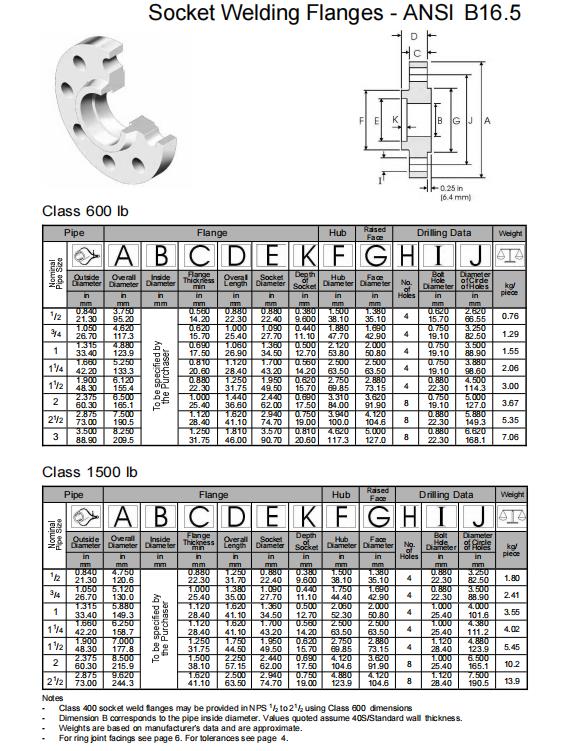

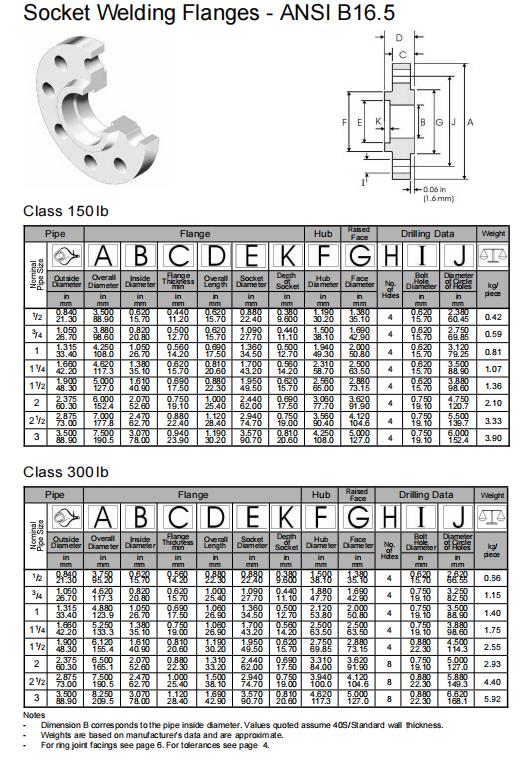

3. Manufacturing standards: ANSI B16.5, HG20619-1997, GB/T9117.1-2000-GB/T9117.4-200, HG20597-1997.

4. Connection method: flange nut, bolt connection.

5. Production process: professional overall forging, forging and manufacturing, etc.

6. Processing method: high-precision CNC lathe turning, ordinary lathe precision turning, argon arc welding and other processing.

7. Scope of application: boiler and pressure vessel, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow food and other industries.

What is the difference between slip-on flange and socket welding flange?

1. The difference between the surface of the slip-on flange and the socket welding flange is that the inner diameter of the socket welding flange has a small step, while the slip-on flange does not, which can be described in the following pictures.

2. The designed pressure bearing range is different, and the flat welding flange with neck is applicable to PN10-PN40; Socket welding flange is applicable to PN10-PN100

3. There is only one welding spot on the outside of the socket welding flange, and one welding spot on the inside and outside of the neck flat welding flange, a total of two welding spots.

4. The English name of the slip-on flange is so flange, while the English name of the socket welding flange is sw flange

5. The application of the neck flat welding flange and the socket welding flange are also different. The socket welding flange is suitable for the connection of small diameter, high pressure and high temperature pipes, and the neck flat welding flange is suitable for medium and low pressure pipes

6. The welding performance of the neck flat welding flange is a little better than that of the socket welding flange