Product Presentation

In a piping system, an elbow is a fitting that changes the direction of a run. A kind of connecting pipe fitting commonly used in pipeline installation, connecting two pipes with the same or different nominal diameters to make the pipeline turn at a certain angle, and the nominal pressure is 1-1.6Mpa. The common angles are 45 ° and 90 ° 180 °. In addition, there are 60 ° and other abnormal angle elbows required by the project. The materials of elbows include cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, nonferrous metals and plastics. The common connection methods with pipes include direct welding, flange connection, hot melt connection, electric melt connection, threaded connection and socket connection.Pressure Rating

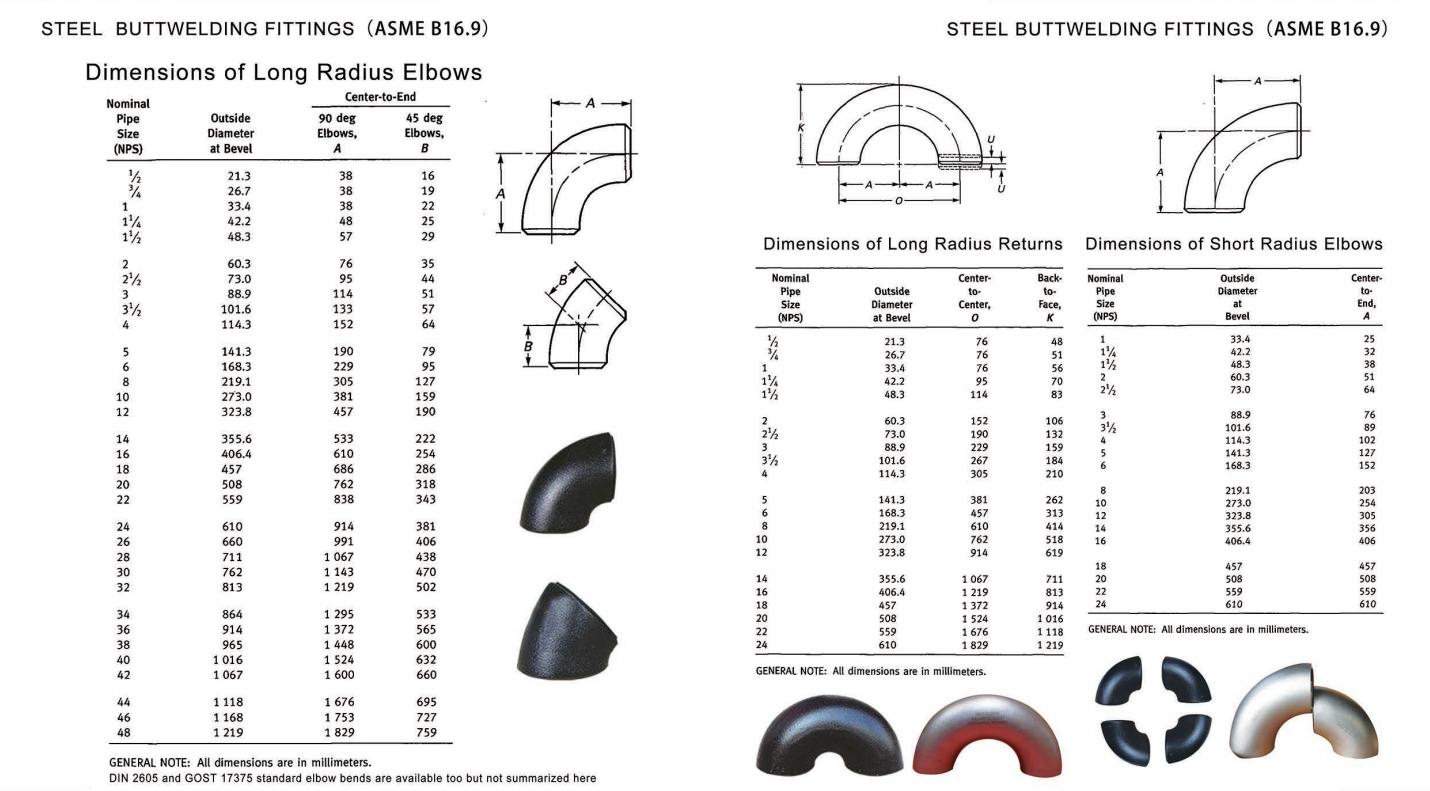

Sch5s、Sch10s、Sch10、Sch20、Sch30、Sch40s、STD、Sch40、Sch60、Sch80s、XS; Sch80、SCH100、Sch120、Sch140、Sch160、XXS; The most commonly used are STD and XS.How to check stainless steel elbow after installation

1. Before installation must strictly check the stainless steel elbow each standard, check whether the diameter meets the requirements of use. In addition, we should ensure that there can be no problems in the transportation process and make preparations before installation. 2. When installing, the connection mode of stainless steel elbow can be directly installed on the pipeline and installed according to the position used. Generally speaking, the installation can be placed at will on the pipeline, but in order to facilitate the maintenance of the later period, it is necessary to pay attention to the stainless steel elbow media should be upstream below the longitudinal valve disc, and stainless steel elbow can only be installed horizontally. 3. Stainless steel elbow installation should pay attention to the sealing, to prevent leakage, thus affecting the operation. 4. Stainless steel elbow valve packing gland bolts should be tightened, can not be pressed into a crooked shape, so as not to cause the movement of the valve stem leakage.Diamensional Data