Product Description

Forged Fittings-threaded tees

High pressure resistance The forged fittings include Socket-Welding elbows, tees and crosses Socket-Welding couplings, Caps Threaded elbows, tees, and crosses Threaded couplings, Caps Plugs and Bushings| Size | 1/8" to 4"(DN6 - DN100) |

| Pressure rating | 2000lbs 3000lbs 6000lbs |

| End type | Threaded(FNPT) Female equal or reducing |

| Steel grade | A105 A350 LF2 F304 F316L F321 |

| HS code | 730799 730793 730729 730723 |

| Production Capacity | 200 tons/ month |

| Origin | China |

| transport package | cartons & plywood cases |

| Standard: | ASME B16.11 |

| Surface | CNC machined, anti-rust oil, HDG(hot dip galv.) |

| Application | Petrochemical industry;aviation and aerospace industry;pharmaceutical industry,gas exhaust; power plant; ship building; water treatment, etc. |

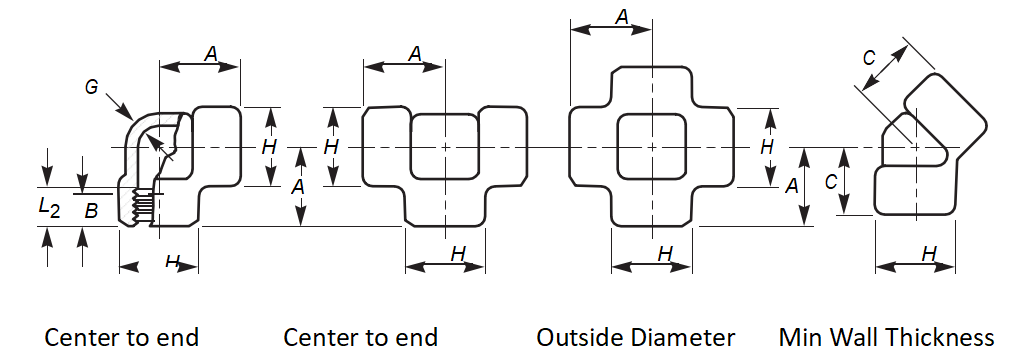

Threaded 90 DEG elbows tees crosses and 45 Deg elbows

Min L of thread

Min L of thread | Pipe Size | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | 2000 | 3000 | 6000 | B | L2 |

| 1⁄8 | 21 | 21 | 25 | 17 | 17 | 19 | 22 | 22 | 25 | 3.18 | 3.18 | 6.35 | 6.4 | 6.7 |

| 1⁄4 | 21 | 25 | 28 | 17 | 19 | 22 | 22 | 25 | 33 | 3.18 | 3.30 | 6.60 | 8.1 | 10.2 |

| 3⁄8 | 25 | 28 | 33 | 19 | 22 | 25 | 25 | 33 | 38 | 3.18 | 3.51 | 6.98 | 9.1 | 10.4 |

| 1⁄2 | 28 | 33 | 38 | 22 | 25 | 28 | 33 | 38 | 46 | 3.18 | 4.09 | 8.15 | 10.9 | 13.6 |

| 3⁄4 | 33 | 38 | 44 | 25 | 28 | 33 | 38 | 46 | 56 | 3.18 | 4.32 | 8.53 | 12.7 | 13.9 |

| 1 | 38 | 44 | 51 | 28 | 33 | 35 | 46 | 56 | 62 | 3.68 | 4.98 | 9.93 | 14.7 | 17.3 |

| 11⁄4 | 44 | 51 | 60 | 33 | 35 | 43 | 56 | 62 | 75 | 3.89 | 5.28 | 10.59 | 17.0 | 18.0 |

| 11⁄2 | 51 | 60 | 64 | 35 | 43 | 44 | 62 | 75 | 84 | 4.01 | 5.56 | 11.07 | 17.8 | 18.4 |

| 2 | 60 | 64 | 83 | 43 | 44 | 52 | 75 | 84 | 102 | 4.27 | 7.14 | 12.09 | 19.0 | 19.2 |

| 21⁄2 | 76 | 83 | 95 | 52 | 52 | 64 | 92 | 102 | 121 | 5.61 | 7.65 | 15.29 | 23.6 | 28.9 |

| 3 | 86 | 95 | 106 | 64 | 64 | 79 | 109 | 121 | 146 | 5.99 | 8.84 | 16.64 | 25.9 | 30.5 |

| 4 | 106 | 114 | 114 | 79 | 79 | 79 | 146 | 152 | 152 | 6.55 | 11.18 | 18.67 | 27.7 | 33.0 |