Brief Introduction

Plate-type flat welding flange is the most common flange at present. It is popularly said that the pipe is inserted into the flange for welding

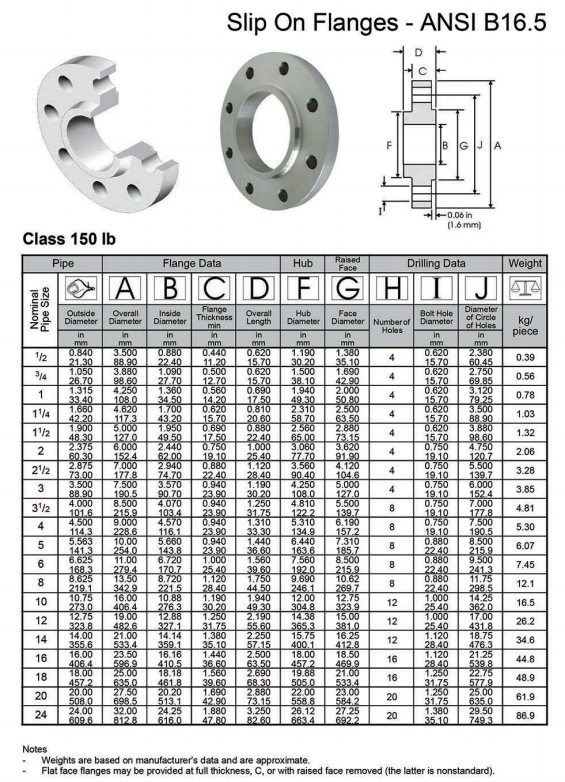

Specification and model: DN15-DN2000

Pressure rating: PN2.5, PN6, PN10, PN16, PN25, PN40, PN63, PN100;

Common material: ASTM304 SUS304

Features of stainless steel plate flat welding flange: beautiful appearance, smooth surface, acid and alkali resistance, corrosion resistance, strong texture performance;

Scope of application

Plate type flat welding flange has the advantages of convenient material, simple manufacture, low cost and wide use; However, due to its poor rigidity, it should not be used in chemical process piping systems with requirements of supply and demand, flammability, explosiveness and high vacuum, and in highly and extremely hazardous situations.

In addition, due to its good comprehensive performance, the flat welding flange is widely used in chemical engineering, construction, water supply, drainage, oil, light and heavy industry, refrigeration, sanitation, water heating, fire protection, electric power, aerospace, shipbuilding and other basic projects.

Advantages of stainless steel plate flat welding

1: Good corrosion resistance, heat resistance, low temperature strength and mechanical properties; Good thermal workability, such as stamping and bending, without heat treatment hardening (service temperature - 196 ℃ - 800 ℃).

2: It is resistant to corrosion in the atmosphere. If it is an industrial atmosphere or a heavily polluted area, it needs to be cleaned in time to avoid corrosion.

3: Suitable for food processing, storage and transportation. It has good machinability and weldability.

Maintenance steps

1. Wipe the surface of plate-type flat welding flange to remove dust, debris and other impurities (you can use rags or professional wiping paper).

2. Injection of anti-rust oil and application of lubricating oil. Antirust oil only needs to be injected into the surface layer, and the application of lubricating oil has requirements, and it needs to be applied in an appropriate amount. Neither too much nor too little.

3. The last is to store the flat welding flange in a rain-proof and dry environment. To prevent the erosion of rain or moist air.

Processing technology

The processing technology of plate type flat welding flange in stainless steel flange is generally divided into five types: casting flange, cutting plate flange, large diameter cold rolled flange, large diameter hot rolled flange and forged flange.

1. The casting flange is produced by smelting scrap iron pin, with low cost. Almost all smelting furnaces are small workshops, the material can not be guaranteed, and the process is simple, and there are air holes. The quality is unstable and belongs to low-end technology, which is gradually eliminated.

2. The cutting plate flange is first cut with steel plate, which is generally made of normal steel plate. Small-diameter steel plate is more common. It is easier to process, the tread is flat, and the cost is low. It is also acceptable. It is common for small-diameter and thin flat welding flanges.

3. Large-diameter cold-rolled flange and 304 stainless steel flange have good ductility. Stainless steel flange manufacturers generally use steel plates to cut and roll them, and the material is not good. Because the steel plate is rolled, it needs to be welded. There will be a welded joint in the middle. Although the welded joint can not be seen after processing, it is not recommended to use it on high-pressure pipes